1. Ifilimu yesendlalelo esisodwa

Kudingeka ukuthi ibe sobala, ingabi nobuthi, ingangenisi amanzi, ibe nesikhwama esihle sokuvala ukushisa, ukumelana nokushisa nokubanda, amandla emishini, ukumelana namafutha, ukumelana namakhemikhali, nokuvimba ukuvimba.

2. Isikhwama se-Aluminium foil

U-99.5% we-aluminium ehlanzekile ye-electrolytic iyancibilika futhi icindezelwe ibe yi-foil yi-calender, ekahle njenge-substrate yokupakishwa kwepulasitiki eguquguqukayo.

3. Vacuum evaporation aluminium ifilimu

Ngaphansi kwe-vacuum ephezulu, izinsimbi ezibilayo eziphansi, njenge-aluminium, ziyancibilika futhi zihwamuke futhi zifakwe efilimini yepulasitiki esigubhu sokupholisa ukuze zakhe ifilimu e-aluminium enokukhanya okuhle kwensimbi.

4. I-silicone enamathela

Impahla yokupakisha esobala enezakhiwo ezithiyo eziphakeme kakhulu ezakhiwa ngeminyaka yawo-1980, eyaziwa nangokuthi i-ceramic coating.

5. Glue (eyomile/emanzi) ifilimu eyinhlanganisela

Amafilimu e-Monolayer anezinzuzo ezithile kanye nokubi okungokwemvelo.Indlela yefilimu eyinhlanganisela emanzi: i-substrate eyodwa ihlanganiswe ne-glue bese i-laminated nenye ifilimu ye-substrate, bese yomiswa futhi yelashwe.Uma kuyizinto ezingenayo i-porous, ukomiswa kweglue kungase kube mpofu futhi ikhwalithi ye-membrane ehlanganisiwe izokwehla.Indlela yokugcoba eyomile: Gcoba ingcina ku-substrate, uyeke ingcina yome kuqala, bese ucindezela futhi ulayinise ukuze ubophe amafilimu ama-substrate ahlukene.

6. Extrusion enamathela ehlanganiswe ifilimu

Ku-extruder, i-thermoplastic iphonswa nge-T-die ephepheni, i-foil, i-plastic substrate okufanele ifakwe, noma i-resin extruded isetshenziswa njengesibophezelo esiphakathi, kanti enye i-substrate yefilimu iyashisa.Izinto ezisetshenziswayo zicindezelwa ndawonye ukuze zenze ifilimu eyinhlanganisela “yesemishi”.

7. Ifilimu eyinhlanganisela ye-Coextrusion

Ukusebenzisa ama-extruder amabili noma amathathu, ukwabelana ngefa eliyinhlanganisela, ama-laminates phakathi kwama-thermoplastic amaningana ahambisanayo ukukhiqiza amafilimu noma amashidi amaningi.

8. Ifilimu yokuvimbela ephezulu

Isho into enogqinsi luka-25.4μm ngaphansi kwezimo ezingu-23°C kanye ne-RH65%, izinga lokudlulisa umoya-mpilo lingaphansi kuka-5ml/m.2·d, futhi izinga lokudluliswa komswakama lingaphansi kuka-2g/m2·d.

9. Ifilimu yokugcina kanye nenzalo

I-ethylene gas adsorption membrane, ukwengeza i-zeolite, i-cristobalite, i-silica nezinye izinto kulwelwesi kungamunca igesi ye-ethylene ekhishwa izithelo nemifino futhi kuvimbele ukuvuthwa kwazo ngokushesha okukhulu.

Ifilimu ye-Anti-condensation ne-fogging, indawo yangaphakathi yefilimu yokupakisha yesithelo esiluhlaza inokufiphala okwengeziwe kanye nenkungu, okulula ukubangela isikhutha ekudleni.

Ifilimu ye-Antibacterial, enezela i-synthetic zeolite (SiO2+Al2O3) ngokushintshaniswa kwe-ion kuzinto zepulasitiki, bese wengeza isigcwalisi esingaphili esiqukethe ama-ion esiliva, ukushintshaniswa kwe-ion sodium eyisiliva kuba yi-zeolite yesiliva, futhi indawo yayo inezinto zokulwa namagciwane.

Ifilimu ye-infrared fresh-reeping ifilimu ihlanganiswe ne-ceramic filler efilimu yepulasitiki, ukuze ifilimu ibe nomsebenzi wokukhiqiza imisebe ye-infrared ekude, engakwazi kuphela ukuvala inzalo, kodwa futhi isebenze amaseli esithelweni esiluhlaza, inomsebenzi wokugcina ubusha.

10. Ifilimu yokupakisha ye-Aseptic

Ikakhulukazi esetshenziswa ekukhiqizeni ukupakishwa kwe-aseptic kokudla nemithi, iyadingeka ukuthi ibe: ukumelana nokuvala inzalo;izakhiwo ezivimbelayo eziphezulu namandla;ukushisa okuhle nokumelana nokubanda (-20 ℃ hhayi brittle);ukumelana nokubhoboza inaliti kanye nokumelana nokugoba okuhle;Iphethini ephrintiwe ngeke yonakale ekubulaleni inzalo kwezinga lokushisa eliphezulu noma ezinye izindlela zokuvala inzalo.

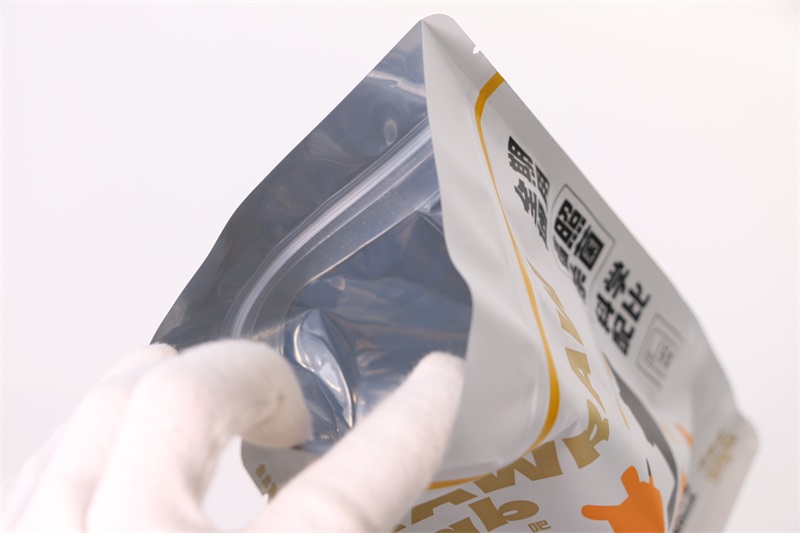

11. Isikhwama sokupheka esimelana nokushisa okuphezulu

Ngawo-1960, i-US Naval Research Institute yaqala yasungula futhi yayisebenzisa ekudleni kwe-aerospace.Ngemuva kwalokho, iJapan yashesha ukuyithuthukisa futhi yathuthukisa futhi yayisebenzisa ezinhlotsheni ezintsha zokudla okulula.Izikhwama zokupheka ezishisa kakhulu zingahlukaniswa zibe uhlobo olusobala (elinokuphila kweshalofu elingaphezu konyaka owodwa) kanye nohlobo olungenalo obala (elinokuphila kweshalofu elingaphezu kweminyaka emibili), uhlobo lwe-high-barrier kanye nohlobo olujwayelekile.Ngokusho kwezinga lokushisa lokuvala inzalo, lihlukaniswe isikhwama sokupheka sokushisa okuphansi (100 ℃, 30min), isikhwama sokupheka sokushisa okuphakathi (121 ℃, 30min), isikhwama sokupheka sokushisa okuphezulu (135 ℃, 30min).Impahla yongqimba yangaphakathi yesikhwama se-retort yenziwe ngamafilimu ahlukahlukene we-PE (LDPE, HDPE, MPE), amelana nokushisa okuphezulu kwe-CPP noma i-IPP ekhuphukile, njll.

Izinzuzo eziyinhloko zezikhwama zokupheka zokushisa okuphezulu:

①Ukupheka kwezinga lokushisa eliphezulu kungabulala wonke amagciwane, i-121℃/30min ingabulala wonke amagciwane e-botulinum;

②Ingagcinwa ekamelweni lokushisa isikhathi eside ngaphandle kwesiqandisi, futhi ingadliwa ibanda noma ifudumele;

③ Impahla yokupakisha inezinto ezinhle zokuthibela, ezingekho ngaphansi kokudla okusemathinini;

④Ukuphrinta okubuyela emuva, ukuphrinta okuhle nokuhlobisa;

⑤ Udoti kulula ukushiswa.

12. Ifilimu yokupakisha yokushisa ephezulu

Iphuzu lokuncibilika lempahla lingaphezu kuka-200 ° C, elifanele iziqukathi eziqinile eziqinile/ezithambile.

13. Ifilimu yepulasitiki ewohlokayo

Imikhiqizo yepulasitiki eyonakalayo ingahlukaniswa ibe yi-photodegradation, biodegradation, photodegradation kanye ne-biodegradation ngokuya ngendlela yokubola.

14. Shisisa ifilimu eshwabene

Izinto zokwakha ziyi-PP, i-PVC, i-LDPE, i-PER, inayiloni, njll. Okokuqala khipha ifilimu, ekushiseni okungaphezu kwezinga lokushisa elithambile (iphoyinti lokushintsha ingilazi) nangaphansi kwezinga lokushisa elincibilikayo, esimweni esinwebeka kakhulu, sebenzisa i-synchronous noma izinyathelo ezimbili. indlela yokwelula i-flat-die, noma indlela ye-calendering, noma i-solvent Indlela yokukhipha yenza ukunwebeka okuqondile, futhi ama-molecule alulayo apholile ngaphansi kwendawo yokuguqula ingilazi futhi avaliwe.

Isikhathi sokuthumela: Apr-25-2022